TYPX series of ultra-high efficiency frequency control three-phase permanent magnet synchronous motor with frequency control capacity,Widely used in petroleum, chemical, power, transportation, textile, industrial and mining enterprises and electric vehicles, Drag pumping units, elevators, fans, pumps, compressors, belt machines, machine tools and other machinery.

1 Overview

TYPX series of ultra-high efficiency frequency control three-phase permanent magnet synchronous motor (frame number 80-355) (hereinafter referred to as the motor), in accordance with Q / NY-010-2015 "TYPX series of ultra-high efficiency three-phase permanent magnet synchronous Motor technical conditions "manufacturing and in accordance with GB3836.2-2013" permanent magnet synchronous motor energy efficiency limit and energy efficiency rating "manufacturing, motor energy efficiency in line with national energy efficiency standards. The motor structure is fully enclosed or fan-cooled structure, protection class IP55, insulation class F, working system for the S1. The mounting dimensions are the same as for the YE3 series motors.

Motor electrical performance of the implementation of GB / T 22711-2008 "efficient three-phase permanent magnet synchronous motor technical conditions (frame number 132 ~ 280)", and Q / NY-010-2015 "TYPX series of ultra-high efficiency frequency control three phase Yong Magnetic synchronous motor technical conditions "(frame number 80-355). This series of products with frequency control capacity, in the 25% -120% load range, relative to the same specifications of asynchronous motors are more efficient, wide range of economic operation, with significant energy saving effect. The motor temperature is low, under the rated load, the motor temperature rise in 30-50K.

Permanent magnet synchronous motor is widely used in petroleum, chemical, power, transportation, textile, industrial and mining enterprises and electric vehicles, drag pumping units, elevators, fans, pumps, compressors, belt machines, machine tools and other machinery. Frequency conversion permanent magnet synchronous motor has three phase 50Hz power supply operation, with soft start capability. According to user requirements, provide a variety of poles of the motor. The basic frequency of the motor can be designed to any value between 10Hz-100Hz, with a variety of speed of the motor, so that the motor and inverter are working in the design value, and to achieve energy-saving FM frequency, the greatest benefit.

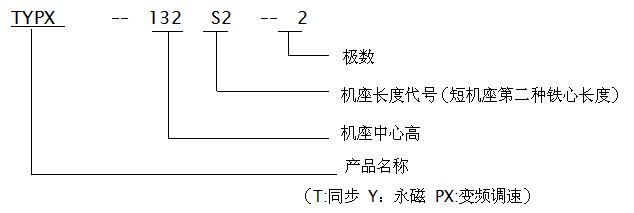

2 .product model and significance

TYPX--132 S2-2

TYPX: T synchronous, Y permanent magnet, PX Variable frequency speed,

132: center height of frame

S2: frame length(short frame second core degree)

2: pole

3. Basic parameters

Rated voltage: 380V, 600 V, 1140 V, 380/660 V, 660/1140 V

FM range: 5-50HZ, 50Hz-100Hz, 5-100Hz

Power range: 0.18-375KW

Insulation class: F

Protection class: IP55

Cooling method: IC411

Installation: IMB3, IMB5, IMB35

4.Terms of use and conditions of use

4.1The motor uses conditions

4.1 .1Ambient air temperature changes with the seasons, generally not more than 40 ℃

4.1.2Ambient air maximum relative humidity of not more than 95% (when the temperature is +25 ℃)

4.1.3Rated voltage:380V、600 V、1140 V、380/660 V、660/1140 V

4.1.4Rated frequency is 50Hz. FM range: 5Hz-50 Hz, 50 Hz -100 Hz, 5 Hz -100 Hz (depending on customer requirements). No-squirrel-cage winding explosion-proof frequency control permanent magnet synchronous motor for the inverter to start (recommended the use of lost frequency converter). Self-starting frequency conversion synchronous motor for 50HZ sinusoidal power supply and inverter for power.

4.1.5 The motor quota is the continuous working standard, the working type is S1,Allow full pressure to start directly.

4.1.6The motor uses F-class insulation, the stator winding temperature rise (resistance method) by 80K assessment (including frame size 315L 2,4 pole and frame size 355, allowing 105K assessment)

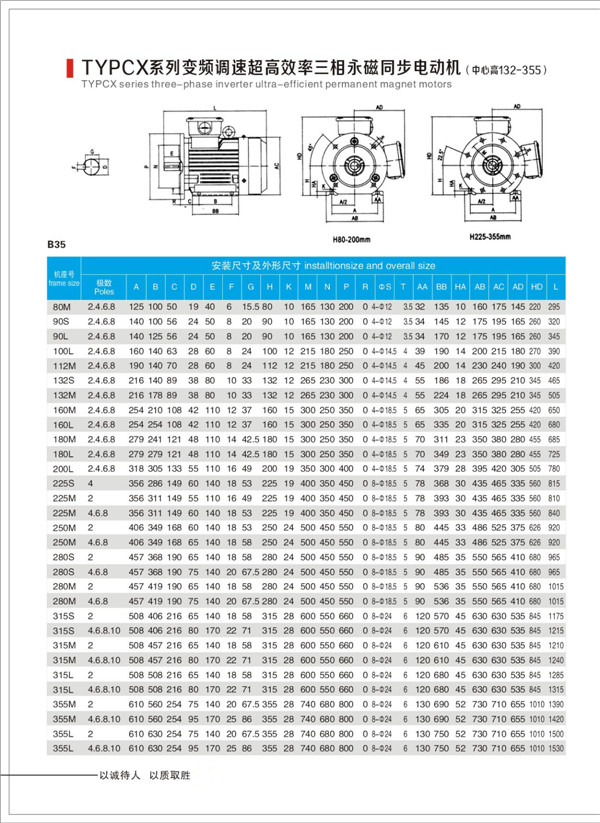

5 Motor mounting structure type and main specifications

5.1 The structure and installation type of this series of motors are shown as below.

Frame Number | Structure and installation code(IM) |

80~160 | B3、B5、B6、B7、B8、V1、V3、V5、V6、V15、V36 |

132~355 | B35 |

180~280 | B3、B5、V1 |

315~355 | B3、V1 |

4.2 The main specifications of this series of motors are shown as below.

Frame number | synchronous speed(r/min) | |||||||||

3000 | 1500 | 1000 | 750 | 600 | 500 | 375 | ||||

power(kW) | ||||||||||

80M | 1 | 0.75 | 0.55 | 0.37 | 0.18 | |||||

2 | 1.1 | 0.75 | 0.55 | 0.25 | ||||||

90 S | 1.5 | 1.1 | 0.75 | 0.37 | ||||||

90 L | 2.2 | 1.5 | 1.1 | 0.55 | ||||||

100L | 1 | 3 | 2.2 |

1.5 | 0.75 | |||||

2 | 3 | 1.1 | ||||||||

112 M | 4 | 4 | 2.2 | 1.5 | ||||||

132S | 1 | 5.5 | 5.5 | 3 | 2.2 | |||||

2 | 7.5 | |||||||||

132M | 1 | -- | 7.5 | 4 | 3 | |||||

2 | 5.5 | |||||||||

160M | 1 | 11 | 11 | 7.5 | 4 | |||||

2 | 15 | 5.5 | ||||||||

160 L | 18.5 | 15 | 11 | 7.5 | ||||||

180 M | 22 | 18.5 | -- | -- | ||||||

180 L | - | 22 | 15 | 11 | ||||||

200L | 1 | 30 | 30 | 18.5 | 15 | 11 | 7.5(5.5) | 5.5 | ||

2 | 37 | 22 | ||||||||

225 S | -- | 37 | -- | 18.5 | 15 | 11(7.5) | 7.5 | |||

225 M | 45 | 45 | 30 | 22 | 18.5 | 18.5(15) | 11 | |||

250 M | 55 | 55 | 37 | 30 | 22 | 22 | 15 | |||

280 S | 75 | 75 | 45 | 37 | 30 | 30 | 18.5 | |||

280 M | 90 | 90 | 55 | 45 | 37 | 37 | 22 | |||

315 S | 110 | 110 | 75 | 55 | 45 | 45 | 37 | |||

315 M | 132 | 132 | 90 | 75 | 55 | 55 | 45 | |||

315 | L1 | 160 | 160 | 110 | 90 | 75 | -- | -- | ||

L | 185 | 185 | — | — | — | -- | -- | |||

L2 | 200 | 200 | 132 | 110 | 90 | 75 | 55 | |||

L3 | 220 | 220 | 160 | — | — | |||||

355S | 1 | 185 | 185 | 160 | 132 | 90 | 75 | 55 | ||

2 | 200 | 200 | ||||||||

355M | 1 | 220 | 220 | 185 | 160 | 110 | 90 | 75 | ||

2 | 250 | 250 | 200 | 132 | 110 | 90 | ||||

355L | 1 | 280 | 280 | 220 | 185 | 160 | 132 | 110 | ||

2 | 315 | 315 | 250 | 200 | 185 | 160 | 132 | |||

3 | 355 | 355 | 280 | 220 | 200 | 185 | 160 | |||

4 | 375 | 375 | 315 | 250 | 220 | 200 | 185 | |||

Note: The number 1.2.3 behind the letterS、M、Lrespectively represents the different power with same frame and speed. | ||||||||||